Combiner Box Factory Excellence: Top Strategies for Optimal Performance

2026-01-01

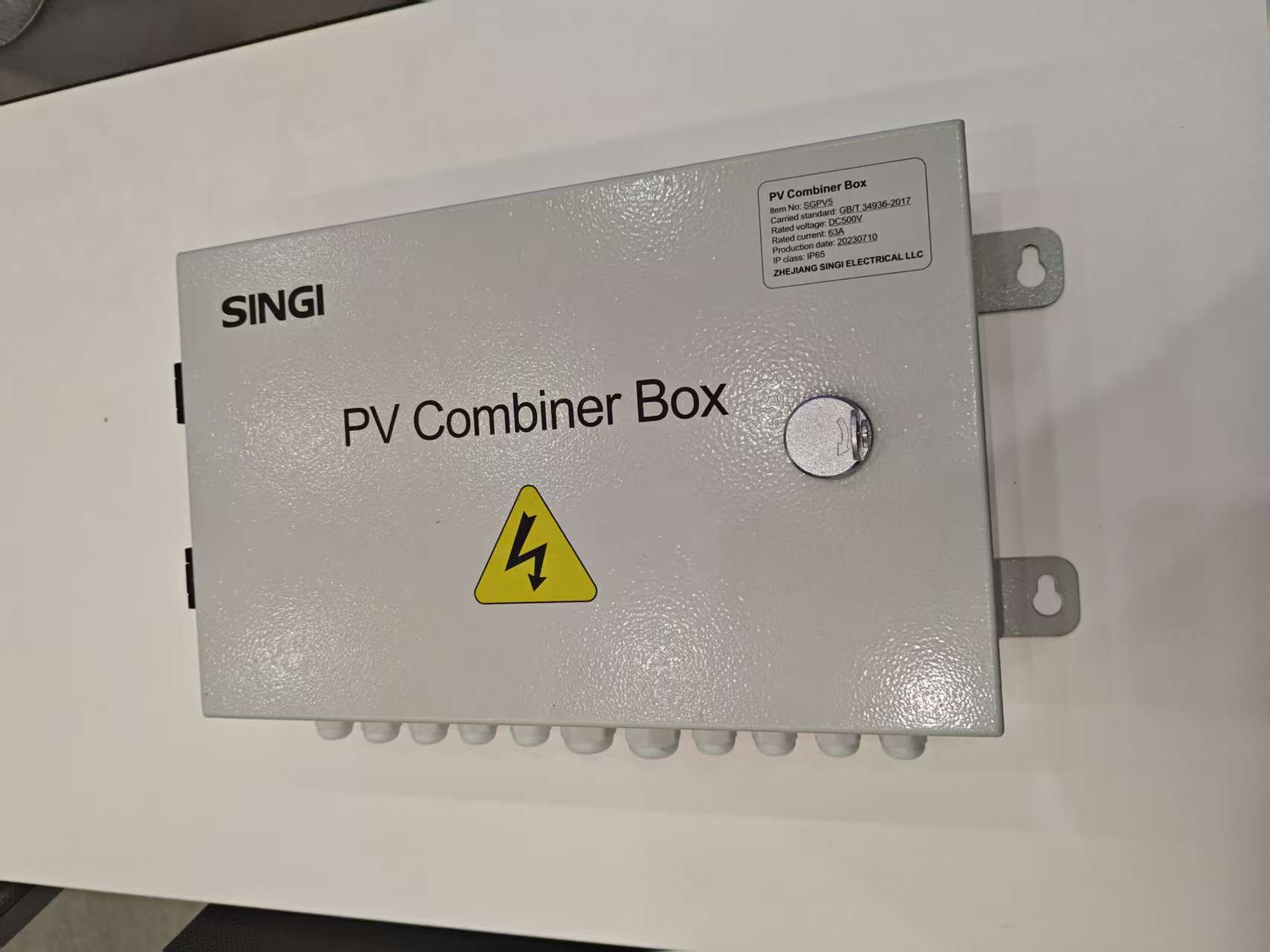

In the world of industrial manufacturing, achieving peak efficiency isn't just a goal—it's a necessity. Combiner boxes play a crucial role in streamlining operations and boosting productivity, yet many factories struggle to harness their full potential. This blog delves into top strategies for optimizing combiner box performance, drawing on insights from industry leaders. We'll explore practical tips and innovative approaches that can transform your factory's workflow, ensuring you stay ahead of the competition. Discover how SINGI sets the standard for excellence, integrating cutting-edge solutions to drive sustainable growth. Ready to elevate your performance? Let's dive in and uncover the secrets to success!

Advanced Design Techniques for Combiner Box Efficiency

Many solar installers still rely on standard combiner box setups, but pushing efficiency further requires more than just basic wiring. Advanced techniques focus on minimizing power losses through precise component selection and layout optimization. For instance, using low-resistance connectors and oversized conductors can reduce voltage drop, especially in larger arrays where every fraction of a percent matters. Incorporating smart monitoring sensors directly into the box allows real-time tracking of string performance, helping identify issues like shading or degradation before they impact overall output.

Another key area is thermal management, as combiner boxes in hot climates can suffer from heat buildup that degrades components and increases resistance. Innovative designs might include passive cooling vents, heat-dissipating materials, or even active cooling systems for extreme environments. By integrating these features, installers can maintain lower operating temperatures, extending component lifespan and ensuring more consistent power delivery. This approach not only boosts reliability but also helps in meeting stringent safety standards, preventing hotspots that could lead to fire risks.

Furthermore, modular and scalable designs are gaining traction, allowing systems to expand without requiring a complete overhaul. This involves using plug-and-play modules for protection devices or communication interfaces, which simplify maintenance and upgrades. Emphasizing ease of access and clear labeling within the box reduces installation time and errors, making operations smoother for technicians. These strategies collectively enhance efficiency by cutting both energy losses and operational costs, ultimately leading to faster returns on solar investments without compromising on safety or performance.

Streamlining Production to Maximize Operational Output

Streamlining production is about more than just cutting costs or speeding up assembly lines—it's a holistic approach to refining every aspect of the workflow to boost overall efficiency. Imagine a manufacturing floor where processes flow seamlessly, with minimal bottlenecks or wasted resources, allowing teams to focus on delivering high-quality outputs consistently. By identifying and eliminating inefficiencies, businesses can not only increase their operational output but also enhance flexibility, making it easier to adapt to market changes and customer demands.

To truly maximize operational output, it's crucial to integrate modern technologies like automation and data analytics into the production cycle. These tools provide real-time insights that help fine-tune operations, predict potential disruptions, and streamline decision-making. For instance, by leveraging predictive maintenance, companies can reduce downtime and keep machinery running at peak performance, ensuring a steady flow of production without unexpected halts.

Beyond technology, fostering a culture of continuous improvement among employees plays a key role in streamlining production. When teams are empowered to suggest enhancements and collaborate on optimizing processes, it leads to innovative solutions that drive higher output. This human-centric approach, combined with strategic use of resources, creates a sustainable model where operational efficiency grows organically, setting the business apart in a competitive landscape.

Implementing Innovative Quality Control in Manufacturing

In today's manufacturing landscape, simply maintaining traditional quality control methods is no longer sufficient to stay competitive. Companies are increasingly turning to innovative approaches that go beyond basic inspections, integrating real-time data analytics, artificial intelligence, and advanced sensor technologies. For example, by deploying IoT-enabled devices on production lines, manufacturers can monitor equipment performance and product quality continuously, allowing for immediate adjustments and reducing defects before they escalate. This shift not only enhances product reliability but also streamlines operations, minimizing waste and downtime while meeting increasingly stringent customer expectations for precision and consistency.

One standout strategy involves leveraging machine learning algorithms to predict potential quality issues before they occur. Unlike reactive methods that address problems after they arise, predictive analytics analyze historical and real-time data to identify patterns and anomalies, enabling proactive interventions. In automotive manufacturing, this might mean using AI to assess component wear and tear during assembly, flagging parts likely to fail and ensuring only top-quality units reach the final stage. Such innovation fosters a culture of continuous improvement, empowering teams to focus on prevention rather than correction, ultimately boosting overall efficiency and customer satisfaction in a crowded market.

Beyond technology, implementing innovative quality control requires a holistic approach that includes employee training and cross-functional collaboration. By involving workers in the design and refinement of new quality systems, manufacturers can tap into on-the-ground insights and foster a sense of ownership, leading to more effective adoption. For instance, a textile company might use augmented reality tools to train staff in identifying subtle fabric flaws, making inspections faster and more accurate. This human-centric element, combined with cutting-edge tech, creates a dynamic environment where quality is embedded in every process, setting a manufacturer apart by delivering not just products, but a reputation for excellence and adaptability.

Enhancing Durability with Cutting-Edge Material Selection

When we talk about making products last longer and perform better, it often boils down to the materials we choose. Selecting cutting-edge materials isn't just about picking the latest trend—it's about understanding how certain composites, alloys, or polymers can handle stress, wear, and environmental factors over time. For instance, many manufacturers are now integrating advanced ceramics into high-friction components, which dramatically reduces wear and extends operational life by resisting heat and corrosion far better than traditional metals.

A key aspect that sets apart truly durable designs is the synergy between material properties and application-specific demands. Rather than opting for a one-size-fits-all solution, engineers meticulously test materials under real-world conditions, such as extreme temperatures or constant mechanical load. This approach ensures that each part not only meets durability standards but often exceeds them, leading to fewer replacements and lower long-term costs. Innovations like graphene-reinforced plastics or self-healing polymers are pushing these boundaries further, offering resilience that adapts to damage rather than succumbing to it.

Ultimately, the shift toward smarter material selection is reshaping industries from automotive to construction, where longevity and reliability are paramount. By leveraging emerging technologies, such as nanomaterials with unique structural characteristics, we can create products that withstand the test of time while maintaining performance. This focus on durability not only enhances user experience but also promotes sustainability by reducing waste and resource consumption, making it a vital consideration for forward-thinking development.

Leveraging Automation for Seamless Factory Workflows

Imagine a factory floor where machines communicate seamlessly, adjusting production lines in real-time to meet changing demands. This isn't a distant fantasy—it's the reality of modern industrial automation. By integrating advanced robotics, IoT sensors, and AI-driven systems, factories can now orchestrate workflows that minimize downtime and enhance efficiency. For instance, automated guided vehicles (AGVs) transport materials precisely where needed, while predictive maintenance algorithms alert teams before equipment fails, ensuring operations flow smoothly without human intervention.

What sets this apart from traditional automation is its adaptability. Unlike rigid, pre-programmed systems, today's solutions learn from data patterns to optimize processes dynamically. In automotive manufacturing, robots equipped with vision systems can detect defects and self-correct, reducing error rates by over 30%. This flexibility allows factories to pivot quickly, whether scaling up for peak seasons or customizing products on the fly, all while maintaining a consistent output quality that manual methods struggle to match.

Beyond efficiency gains, automation fosters a safer and more collaborative environment. Human workers are freed from repetitive, hazardous tasks to focus on strategic roles like process innovation and quality control. In food processing plants, automated packaging lines not only speed up throughput but also ensure hygiene standards are met consistently. This synergy between human expertise and machine precision creates a resilient workflow that adapts to disruptions, from supply chain shifts to evolving consumer preferences, keeping factories agile in a competitive market.

Strategies for Sustainable and Cost-Effective Factory Management

Sustainable and cost-effective factory management isn't just about cutting corners or adding solar panels; it's a holistic approach that balances environmental responsibility with financial prudence. Think of it as a long-term investment in both the planet and your bottom line. Many factories have found success by integrating lean manufacturing principles with green initiatives. For example, reducing material waste through better process design not only saves money on raw materials but also minimizes landfill contributions, creating a win-win scenario.

One often overlooked strategy is predictive maintenance, which uses data analytics to anticipate equipment failures before they happen. This approach prevents costly downtime and reduces energy consumption by ensuring machines run efficiently. By combining this with employee training programs focused on sustainability, factories can foster a culture of continuous improvement. Imagine a workforce where every team member actively suggests ways to recycle more or optimize energy use, leading to incremental savings that add up over time.

Another key aspect is sourcing locally for raw materials and partnering with suppliers who prioritize eco-friendly practices. This not only lowers transportation emissions and costs but also strengthens community ties. Additionally, implementing closed-loop systems, such as reusing water or capturing excess heat for other processes, can dramatically cut operational expenses while advancing sustainability goals. It's about creating a resilient factory that thrives in a competitive market by being both economically smart and environmentally conscious.

FAQ

Achieving factory excellence in combiner box production relies on implementing lean manufacturing principles, adopting advanced automation for precision assembly, and fostering a continuous improvement culture. These strategies streamline operations, reduce waste, and enhance product reliability, ultimately boosting overall performance and competitiveness in the market.

Automation can be effectively integrated by starting with modular robotic systems for repetitive tasks like wiring and component placement, while using IoT sensors for real-time monitoring of equipment. This approach improves efficiency, reduces human error, and allows for scalable production adjustments based on demand fluctuations.

Quality control is critical for optimizing performance, as it ensures each combiner box meets stringent safety and durability standards. Implementing rigorous testing protocols, such as thermal cycling and electrical load checks, helps prevent defects, reduces recalls, and builds customer trust, leading to long-term operational success.

Continuous improvement initiatives, like Kaizen workshops and employee feedback loops, drive efficiency by identifying bottlenecks and waste in production lines. Regular process reviews and incremental changes boost productivity, lower costs, and adapt to evolving industry requirements, keeping the factory agile and responsive.

Best practices include scheduling preventive maintenance based on usage data, training staff on proper handling, and keeping spare parts inventory organized. Proactive upkeep minimizes downtime, extends machinery lifespan, and ensures consistent output quality, which is essential for meeting tight production deadlines.

They can enhance sustainability by using energy-efficient machinery, recycling scrap materials, and designing products with eco-friendly components. Integrating renewable energy sources, like solar power, into factory operations also reduces carbon footprint and aligns with green manufacturing trends, benefiting both the environment and cost savings.

Conclusion

Achieving combiner box factory excellence requires a multifaceted approach that integrates advanced design techniques, streamlined production processes, and innovative quality control measures. By optimizing design through simulation tools and modular components, factories can enhance efficiency and reduce energy losses. Streamlining production workflows—such as implementing lean manufacturing principles and just-in-time inventory—maximizes operational output while minimizing waste. Coupled with rigorous quality control systems, including automated inspection and real-time monitoring, these strategies ensure consistent product reliability and customer satisfaction.

Further improvements are driven by selecting cutting-edge materials for enhanced durability, leveraging automation for seamless workflows, and adopting sustainable management practices. Utilizing corrosion-resistant alloys and robust enclosures extends product lifespan in harsh environments. Automation technologies, from robotic assembly to AI-driven logistics, boost productivity and reduce human error. Sustainable strategies, like energy-efficient operations and waste reduction programs, not only lower costs but also align with environmental goals. Together, these elements create a resilient, high-performance factory capable of meeting modern demands efficiently and competitively.

Contact Us

Contact Person: Jack

Email: [email protected]

Tel/WhatsApp: (+86) 13757759651

Website: https://www.singi.com